Combustion-induced particulate matter

Population balance modeling of particulate process (particle collision/coagulation, breakage, nucleation, condensation/evaporation (surface growth/dissolution), deposition) in complex dispersed systems, covering particulate matter, soot, PAH, carbon black, nanoparticles, and fluidization; simulation of fiber filtrations of particular matter by Lattice Boltzmann Cellar Automata.

1. Introduction

It is a widespread phenomenon in nature and engineering that combustion produces fine particles. In some cases, we should try our best to reduce the generation of these tiny particles (such as the particulate matters generated by the combustion of fossil fuels). And in other cases we need to maximize yield of these fine particles (such as combustion-synthesized nanoparticles). Insight into the complex physico-chemical mechanisms and dynamics of these fine particles is required from the point of view of controlling the emission of particulate matter or optimizing the combustion generated functional nanomaterials.

2. Research findings

(1) Simulation of sedimentation process of particulate matter in natural environment by PBMC

In order to learn self-purification mechanism of nature to develop efficient removal schemes for particulate matter (PM) from coal combustion, as well as to study the life process of PM exhausting from the chimney in natural environment, quantitative modelling and simulation have been conducted to understand the dry deposition (due to gravitational settlement) and wet deposition (by rainfall) processes of aerosol particles by PBMC simulation.

Mechanical analysis of aerosol particle trapped by raindrops during the rainfall (left) and the relation between rainfall condition and wet deposit aerosol particles (right).

Reference:

[1] Haibo Zhao*, Chuguang Zheng. Monte Carlo solution of wet removal of aerosols by precipitation. Atmospheric Environment, 2006, 40(8): 1510-1525

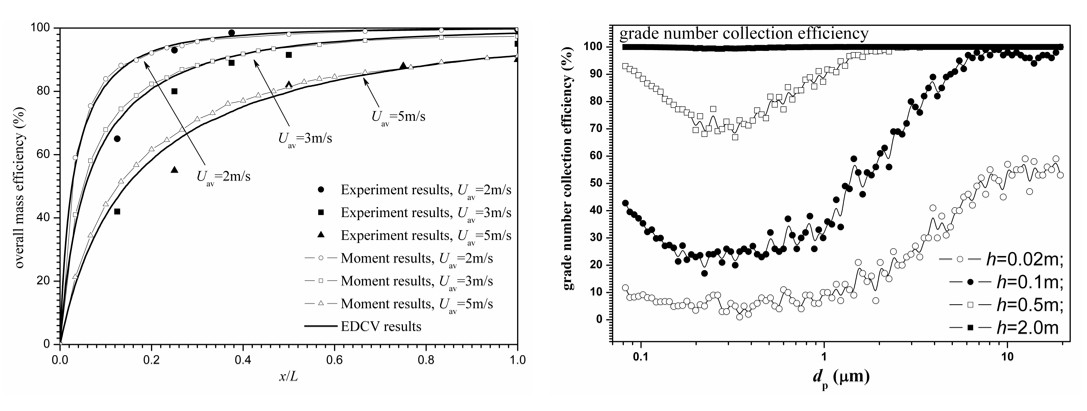

(2) PBMC simulation of collecting process of particulate matter by typical dust-removal equipment

The particle collecting process in conventional dust-removal equipment (e.g., electrostatic precipitator, gravitational wet scrubber, electrostatic enhanced wet scrubber and electric bag filter) have been simulated by PBMC to study the dynamic evolution process of PM under various external fields (e.g., Electric field, gravitational field, captured by droplet collision, captured fiber interception, etc). To optimize and improve the conventional dust-removal technology, capture mechanisms of PM (especially the particle size ranging from 0.1μm to 1μm) have been explored and several tuning parameters and sensitive parameters of new dust-removal technologies have been determined.

Deposited laws of coal-fired inhalable particles in Electrostatic precipitators (left) and wet electrostatic precipitator enhanced (right)

Reference:

[1] Haibo Zhao*, Chuguang Zheng. Modeling of gravitational wet scrubbers with electrostatic enhancement. Chemical Engineering & Technology, 2008, 31(12): 1824-1837.

[2] Haibo Zhao*, Chuguang Zheng. A stochastic simulation for the collection process of fly ashes in single-stage electrostatic precipitators. Fuel, 2008, 87(10-11): 2082-2089

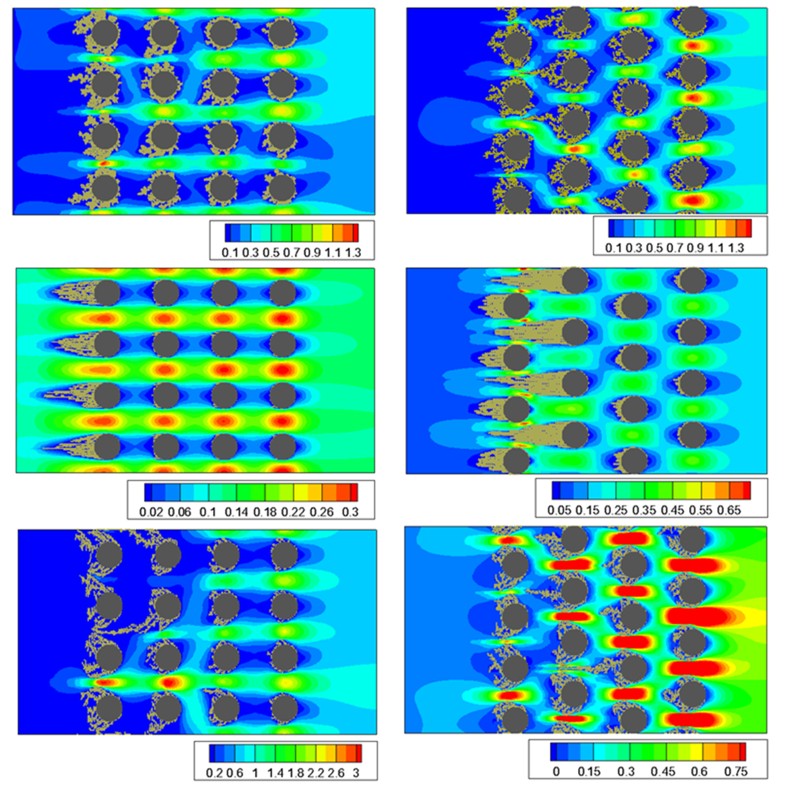

(3) Lattice Boltzmann simulation for the fibrous filtration process of particulate matter

The key issue in the simulation of the filtration process is that the deposited particles serve as the filtration media, influencing the flow field and the subsequent particle deposition. The general gas-solid two phase model is difficult to deal with complex dynamic boundaries. And thus Lattice Boltzmann- Cellular Automata (LB-CA) probabilistic model was used to simulate the steady and unsteady filtration process of regular fibers (with circular cross section), irregular fibers (elliptical, rectangle, trilobal, cross and triangle) and multilayer fibers to investigate the dynamic evolution of pressure drop, capture efficiency, deposition patterns and porosity of dentritic structure, which is conducive to optimizing the design and operation of fibrous filters.

Process of multi-fiber trapping particles (on: Brownian diffusion dominated; the inertial impaction dominated; following: interception dominated)

Reference:

[1] Haoming Wang, Haibo Zhao*, Zhaoli Guo, Chuguang Zheng. Numerical Simulation of Particle Capture Process of Fibrous Filters using Lattice Boltzmann Two-phase Flow Model. Powder Technology, 2012, 227: 111–122

[2] Haoming Wang, Haibo Zhao*, Kun Wang, Yongxiang He, Chuguang Zheng. Simulation of filtration process of multi-fiber filter using lattice-Boltzmann two-phase flow model. Journal of Aerosol Science, 2013, 66: 164-178

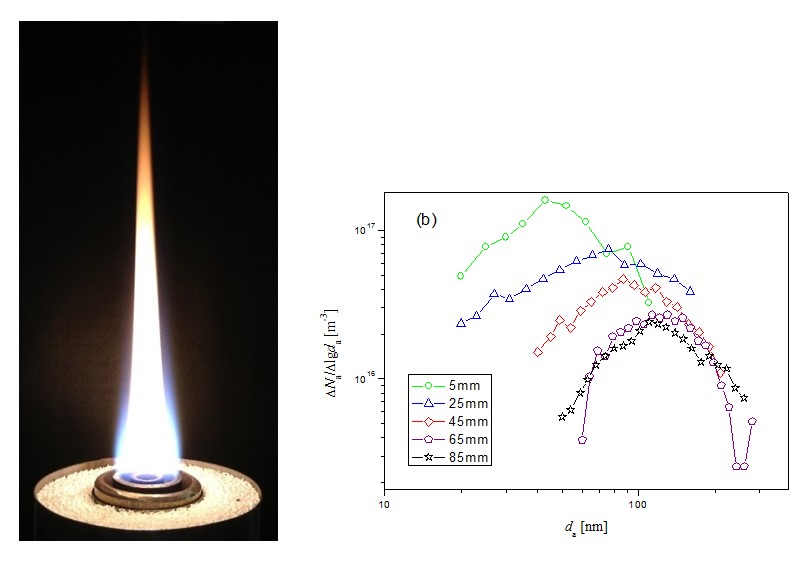

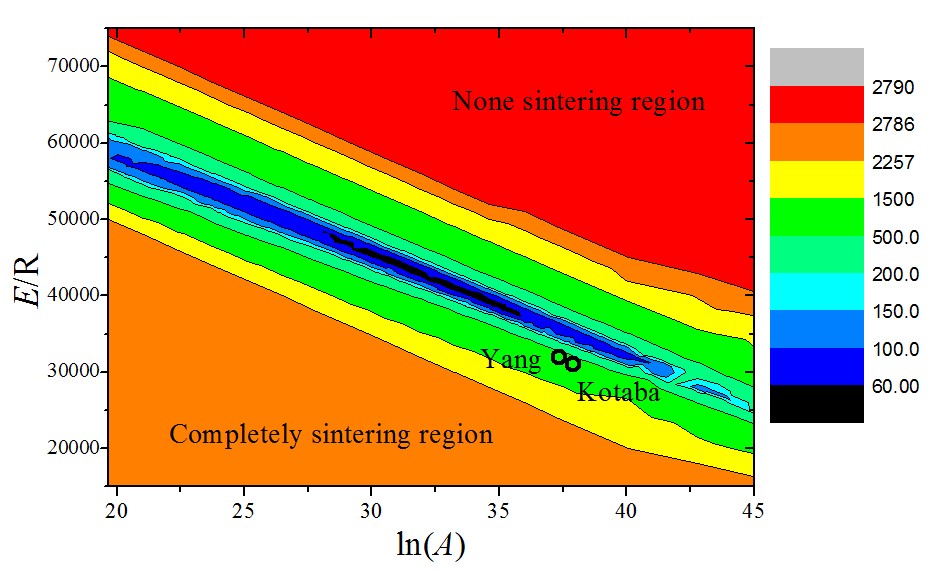

(4) Experimental measurements for the nanoparticle preparation via combustion method and its CFD-PBMC simulation

For the nanoparticle preparation processes via combustion, traditional experimental measurements and numerical simulations of multiphase reactive flows face several challenges, including the tiny time period of the process (usually within millisecond), high gradients of fraction concentration, particle concentration and gas temperature, wide particle size distribution from nanometers to micrometers, extremely large particle number concentration while relatively low mass concentration. A simple while novel dual time-interval sampling at single point (DTSP) method was developed to measure the flame temperature, particle volume fraction, size distribution, and gas velocity simultaneously. At the same time, CFD-PBM simulation has been employed to capture the particle dynamics involved in the preparation process. Based on the numerical simulations and experimental measurements, the inverse problem methodology has been used to identify effective model parameters in the nucleation, sintering and agglomeration kernel models.

(a) Combustion experiment of nanoparticles preparation; (b) Experiment results of agglomerate size distribution;

(c) Inverse identification of sintering mechanic parameters

Reference:

[1] Haibo Zhao*, F. Einar Kruis*, and Chuguang Zheng. Reducing Statistical Noise and Extending the Size Spectrum by Applying Weighted Simulation Particles in Monte Carlo Simulation of Coagulation. Aerosol Science and Technology, 2009, 43(8): 781 - 793

[2] Haibo Zhao*, Chuguang Zheng. A new event-driven constant volume method for solution of the time evolution of particle size distribution. Journal of Computational Physics, 2009, 228(5): 1412-1428.

[3] Xiaoming Hao, Haibo Zhao*, Zuwei Xu, Chuguang Zheng. Population balance-Monte Carlo simulation for gas-to-particle synthesis. Aerosol Science and Technology, 2013, 47(10), 1125-1133

Address: hongshan district in wuhan city, hubei province no road 1037 yu hua zhongke

University of technology state key laboratory of coal combustion, room 214

Zip code: 430074

Telephone: 027-87542417

Scan,can focus on

Scan,can focus onHubei hubei ICP for 05003321-1 42011102000123 male may be prepared

Powered by: StudyStone