Thermoeconomic analysis and optimization of complex energy system (steady-state and dynamic process simulation (Aspen plus), exergy analysis, techno-economic evaluation, thermoeconomic analysis, …), covering oxy-fuel combustion, chemical-looping combustion, Integrated Gasification Combined Cycle, MEA, and pulverized-coal fired power plants; Automation of Electric Power Systems (specialist analysis platform of coal-fired power plants based on web and remote run-time database)

1. Introduction

The coal-fired power plant, carbon capture and storage (CCS) and so on, have the characteristics of being widely involved in different sectors and fields, being widely spanned in time and space, high cost and knowledge intensiveness, strong interaction with society, economics and ecological environment . Therefore it is essential also important to carry out comprehensive evaluation and integrated optimization considering energy-economy-environment effects simultaneously.

2. Research findings

(1) Process simulation of Coal fired power plant

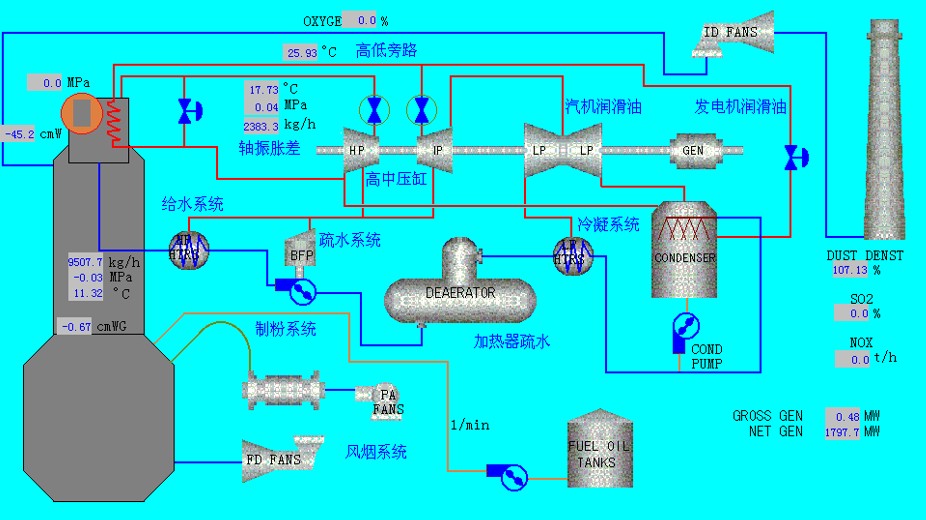

On-line monitoring, system optimization and control, real-time fault diagnosis, reasonable design, safe and economic operation, etc. have become the challenging need of modern large-scale power plant. Remote/local specialist analysis platform of power plant , which is based on Web technology and the advance three-layer structured mode of Browser/Server/Database, has been built to realize the real-time monitoring of power plant operation data, online economic analysis, intelligent search engine, remote simulation, remote fault diagnosis and visualization of thermodynamic calculation.

Web-based real-time monitoring system of coal-fired power plant

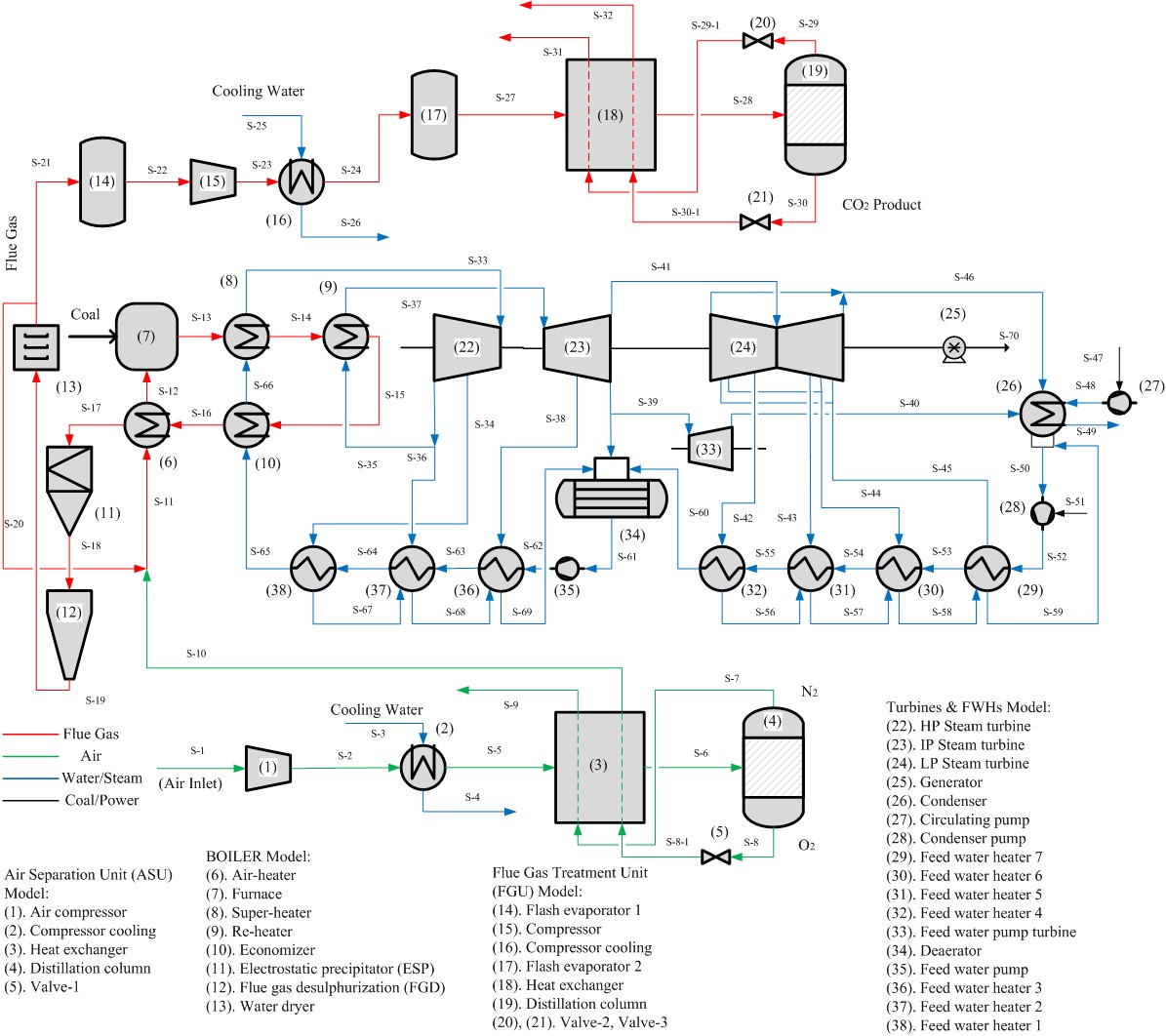

(2) Process simulation of complex energy conversion system

The basis of thermodynamic analysis of coal fired power plant (including boilers, turbines, generators and other subsystems) is to setup a mathematical description of the relationship between the input and output variables of internal interconnected components, that is to say, to establish) mass balance, energy balance of the main equipment (being divided into heat transfer equipment, transmission equipment, equipment expansion and compression equipment) and characteristic equations of thermodynamic properties of the device and simultaneously solve these mathematical equations to achieve process simulation. Commercial software was used for steady-state and dynamic process simulations of conventional coal-fired power plants and new oxyfuel power plants, which lays the foundation for energy-economics-environment analysis and evaluation.

Simulation platform of Oxyfuel power plant

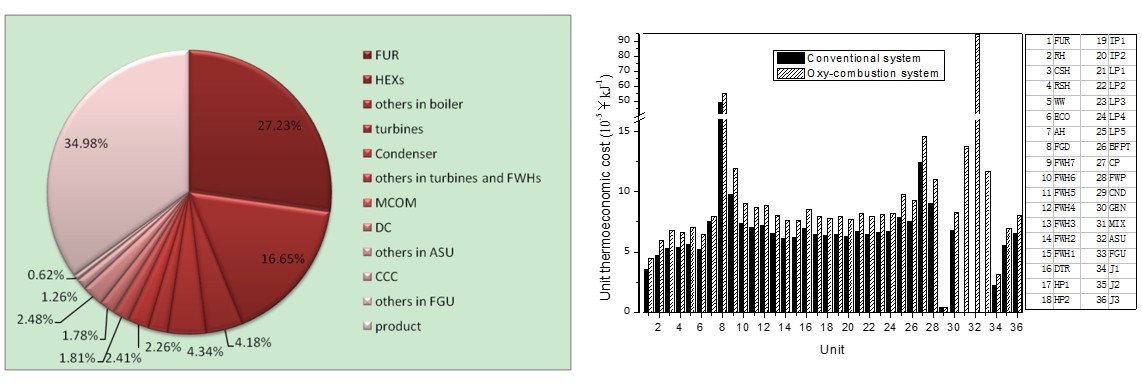

(3) Environthermoeconomic evaluation and analysis

Based on detailed information on material and energy flows from process simulation, the exergy analysis, techno-economic evaluation, environthermoeconomic analysis and evaluation, fault diagnosis and operation optimization on the basis of structured theory of thermoeconomics, were successfully conducted for understanding traditional coal fired power plants and oxyfuel power plants. The thermodynamic process and distribution rule of inherent “cost” were clearly explained. These results are able to provide valuable references for optimization design, high-efficiency and low-cost operation, and even technology selection and energy policy making.

Reference

Address: hongshan district in wuhan city, hubei province no road 1037 yu hua zhongke

University of technology state key laboratory of coal combustion, room 214

Zip code: 430074

Telephone: 027-87542417

Scan,can focus on

Scan,can focus onHubei hubei ICP for 05003321-1 42011102000123 male may be prepared

Powered by: StudyStone